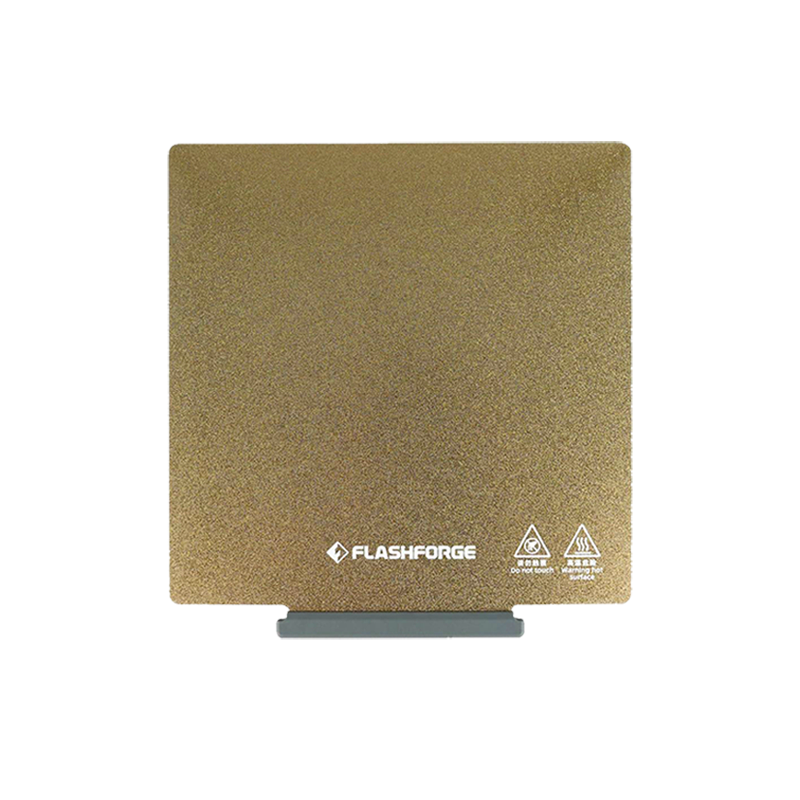

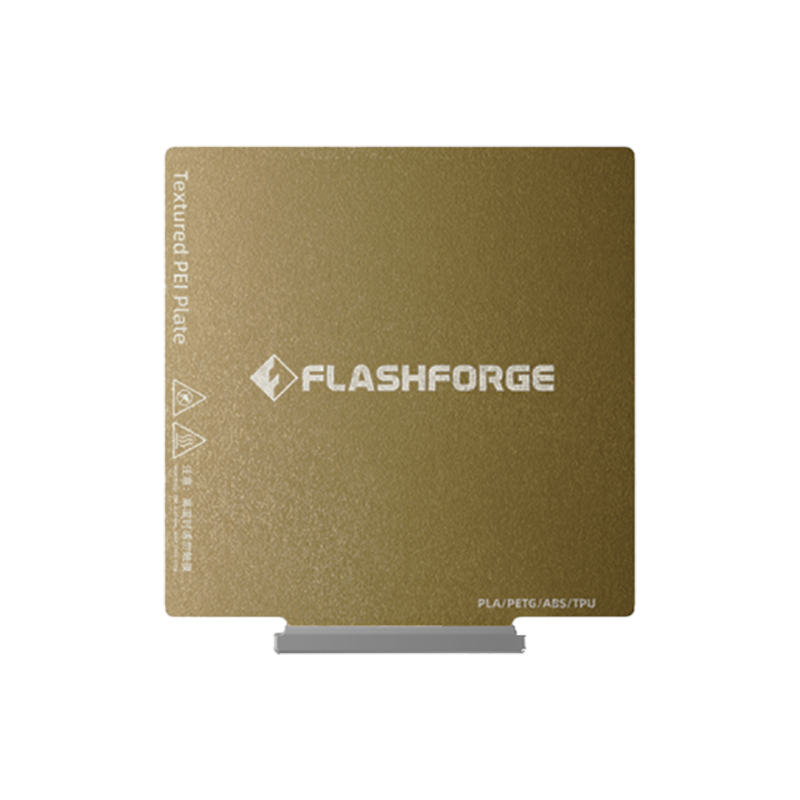

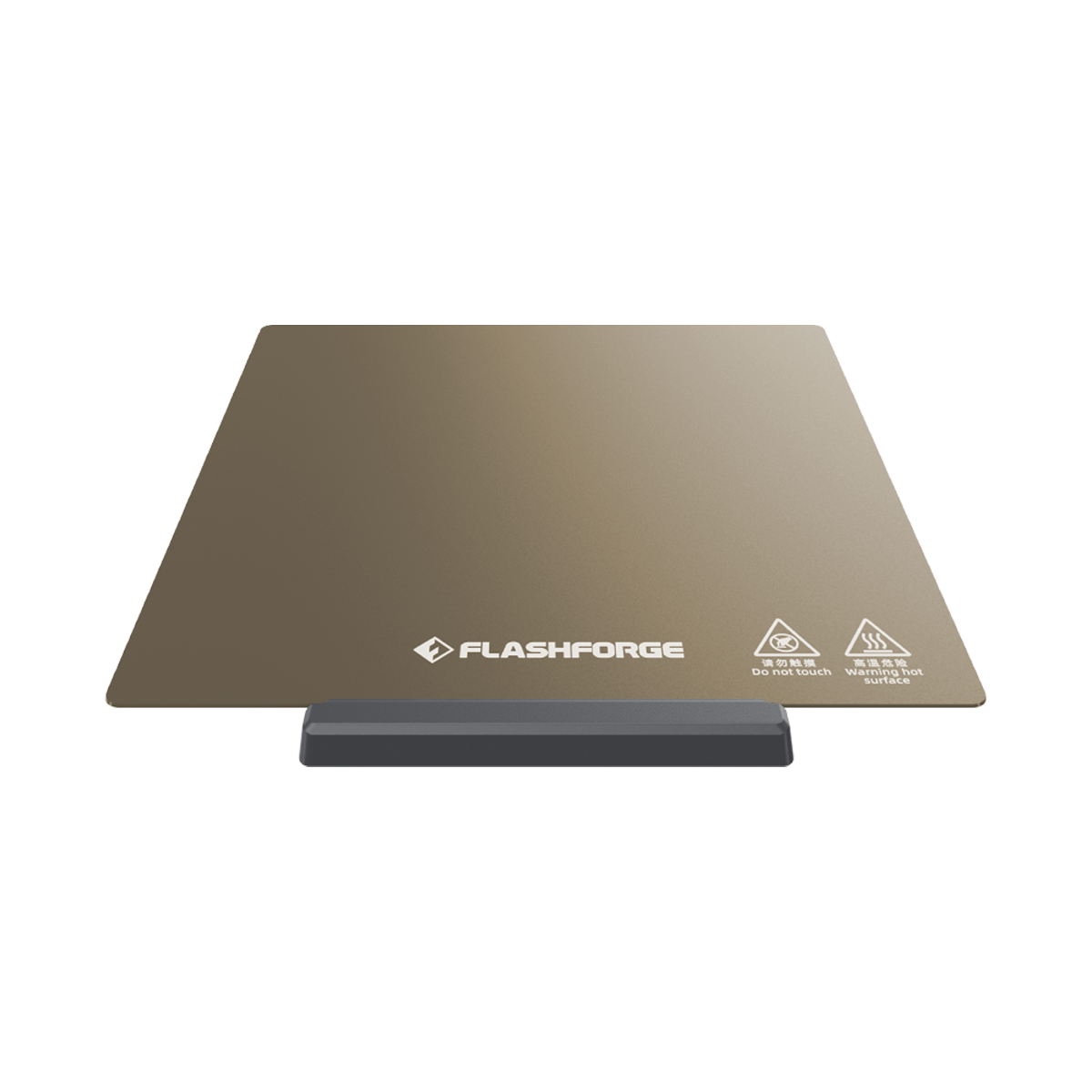

Build Plate for AD5M, AD5M Pro and AD5X

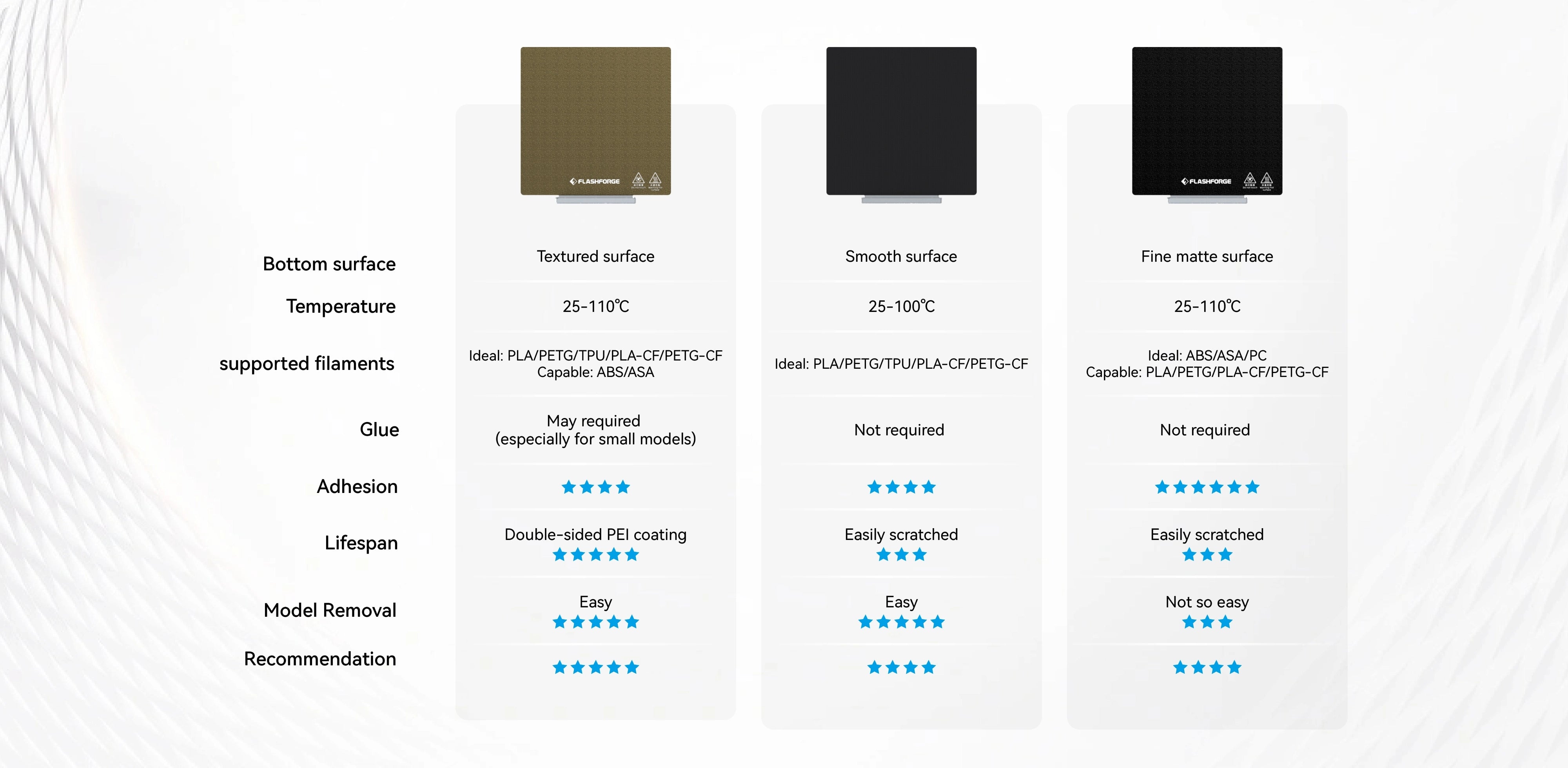

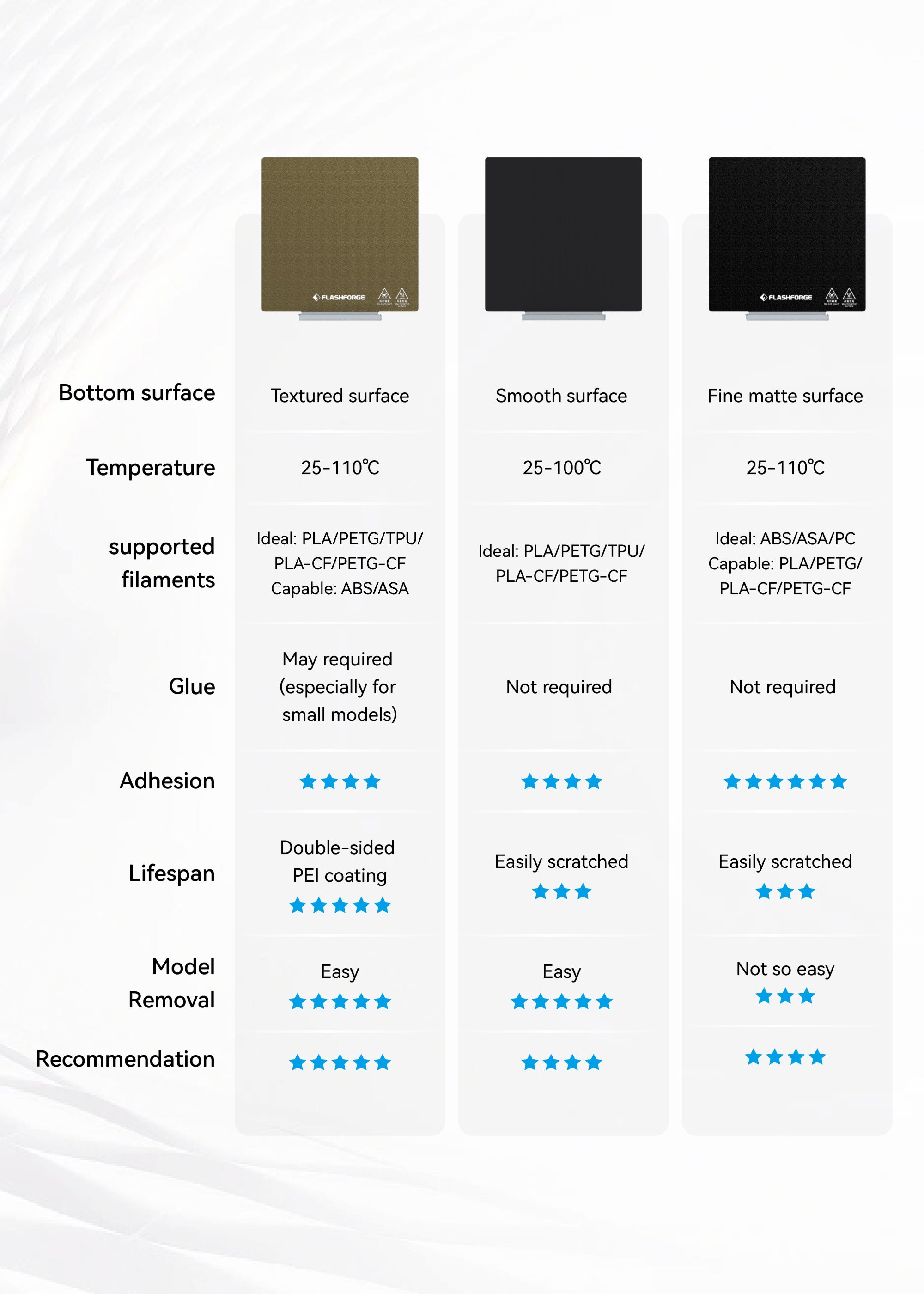

- Smooth PEI Plate: Achieve flawless bottom finishes with excellent adhesion for PLA, PETG, and TPU—no glue needed. Perfect for beginners and hobbyists.

- PEI Powder-Coated Plate: Adds a unique textured finish to models; ideal for artistic designs. Glue may be required for certain filaments.

- Smooth PC Plate: Offers high-temperature stability for advanced materials like ABS, PC, and ASA, with strong adhesion and no glue required.

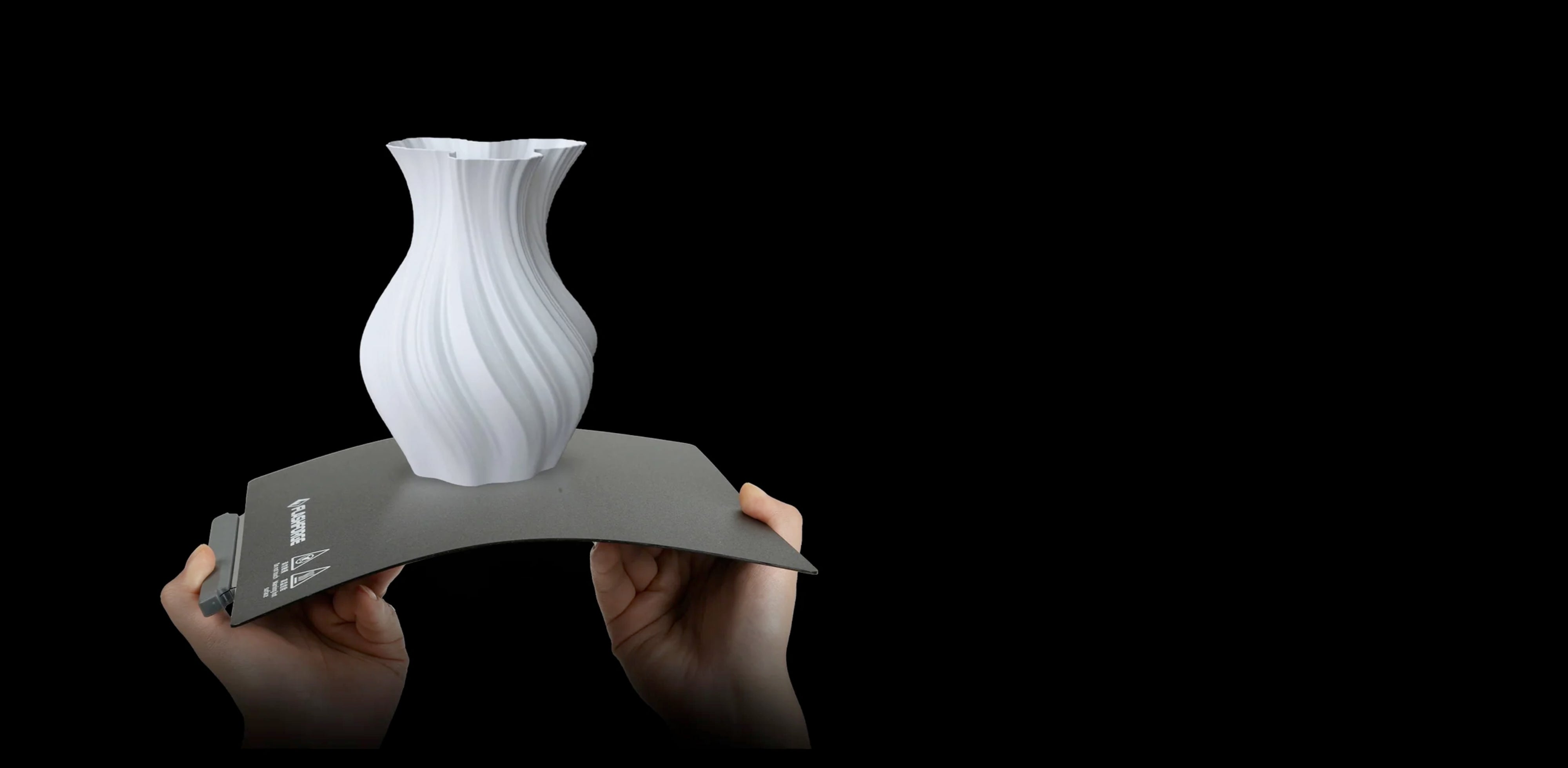

- Effortless Model Removal: Simply cool to room temperature for easy removal. For PC plates, gently bend to release models.

Fast Shipping & 30-Day Return

Fast Shipping

3D printers are shipped from international local warehouses, while accessories come from the China warehouse. Orders with both will be split into multiple packages. 3D printers usually arrive in 2-5 working days, while accessories may take longer due to customs and other factors.

30-Day Return

Flashforge accepts returns for 3D printers within 30 days of delivery. The Return Policy provides details on return options and procedures. For more information, please refer to the return policy

Fast Shipping & 30-Day Return

Fast Shipping

3D printers are shipped from international local warehouses, while accessories come from the China warehouse. Orders with both will be split into multiple packages. 3D printers usually arrive in 2-5 working days, while accessories may take longer due to customs and other factors.

30-Day Return

Flashforge accepts returns for 3D printers within 30 days of delivery. The Return Policy provides details on return options and procedures. For more information, please refer to the return policy

12-Month Warranty

Flashforge offers a 1-year limited warranty for its 3D printers and a 3-month warranty for extruder parts.

12-Month Warranty

Flashforge offers a 1-year limited warranty for its 3D printers and a 3-month warranty for extruder parts.

Secure Payment

We offer a variety of payment channels,including PayPal, Apple Pay, Google Pay, Mastercard, VISA and more.

Our commitment to delivering a frictionless, secure payment experience is fundamental to cultivating lasting trust and satisfaction with our customers.

Secure Payment

We offer a variety of payment channels,including PayPal, Apple Pay, Google Pay, Mastercard, VISA and more.

Our commitment to delivering a frictionless, secure payment experience is fundamental to cultivating lasting trust and satisfaction with our customers.

AD5M Series

Smooth PC Plate: ABS/ASA

Smooth PC Plate: PLA/PETG/TPU/PLA-CF

Upgrade Gold PEI Powder-Coated Plate: PLA/PETG/ABS/ASA/TPU/PLA-CF

The Appropriate Platform Based on Print Needs

The Bottom Surface of Printed Object

Effortless Model Removal

Cooling to room temperature, without the need for external force intervention, the model effortlessly separates from the build plate.

*To remove models from a PC platform, bending the platform is necessary.

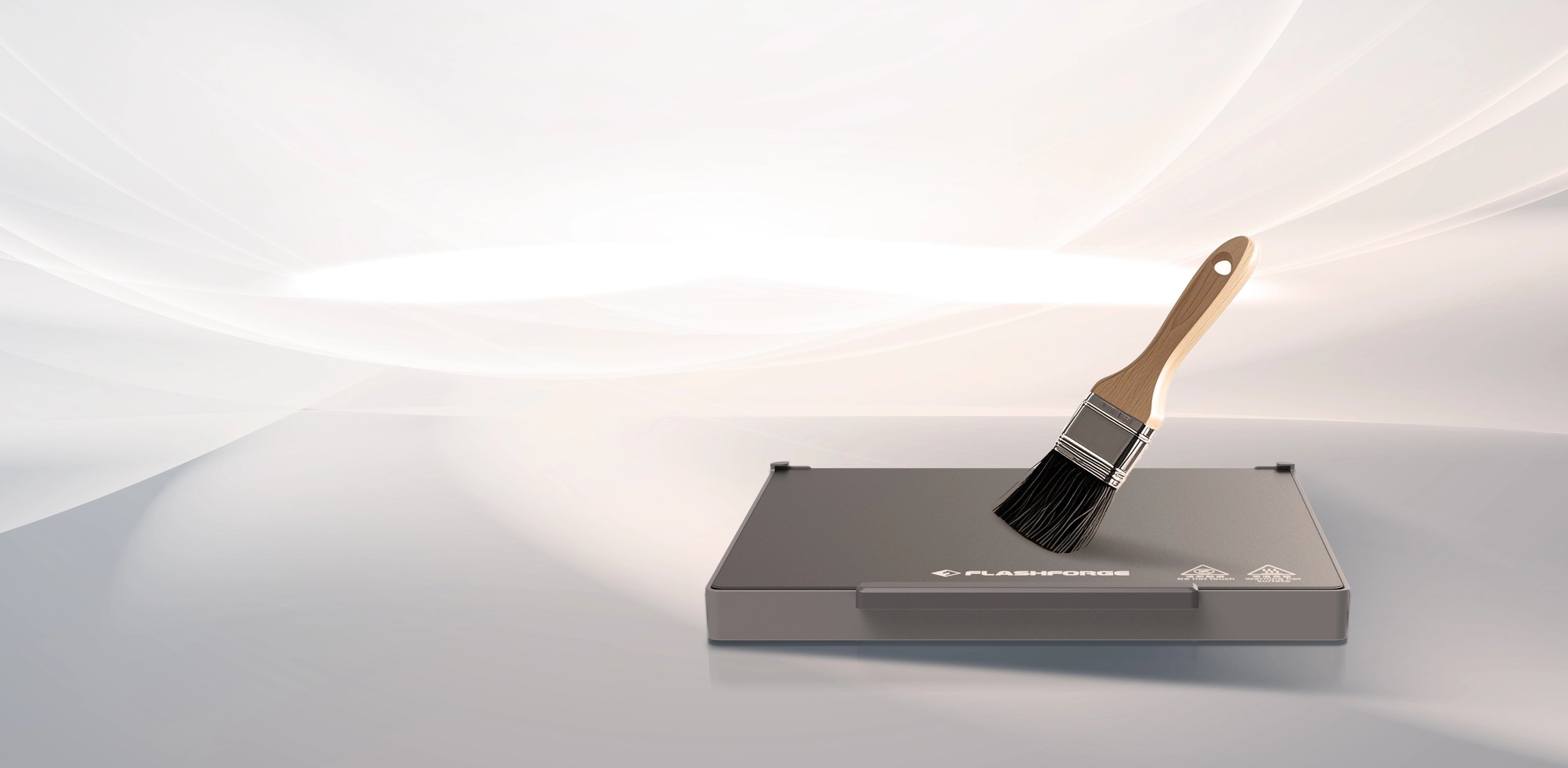

Platform Maintenance

Dust and grease buildup on the platform can reduce adhesion. It's advisable to clean the surface regularly with water and a cleaning agent for optimal adhesion.